Purchase Order Management Tool

Enabling accurate, efficient merchandise management to drive informed business decisions

A centralized tool that enables Nordstrom employees to manage purchase orders with accuracy, efficiency, and traceability streamlining cost calculations and driving informed business decisions.

Launched 2023

Who I worked with

PMs

Engineers

Researcher

UX Writer

Merchandisers

Digital Operators

Supply Chain

Buyers and assistants

3,500+ employees manage 300K–400K purchase orders annually

What led us to improve cost structure on this tool?

As purchase orders scaled, fragmented processes and manual data entry caused errors, slowed approvals, and made it difficult to calculate profitability. Teams lacked a reliable way to validate costs, leading to downstream confusion and delays.

For employees: Operational friction

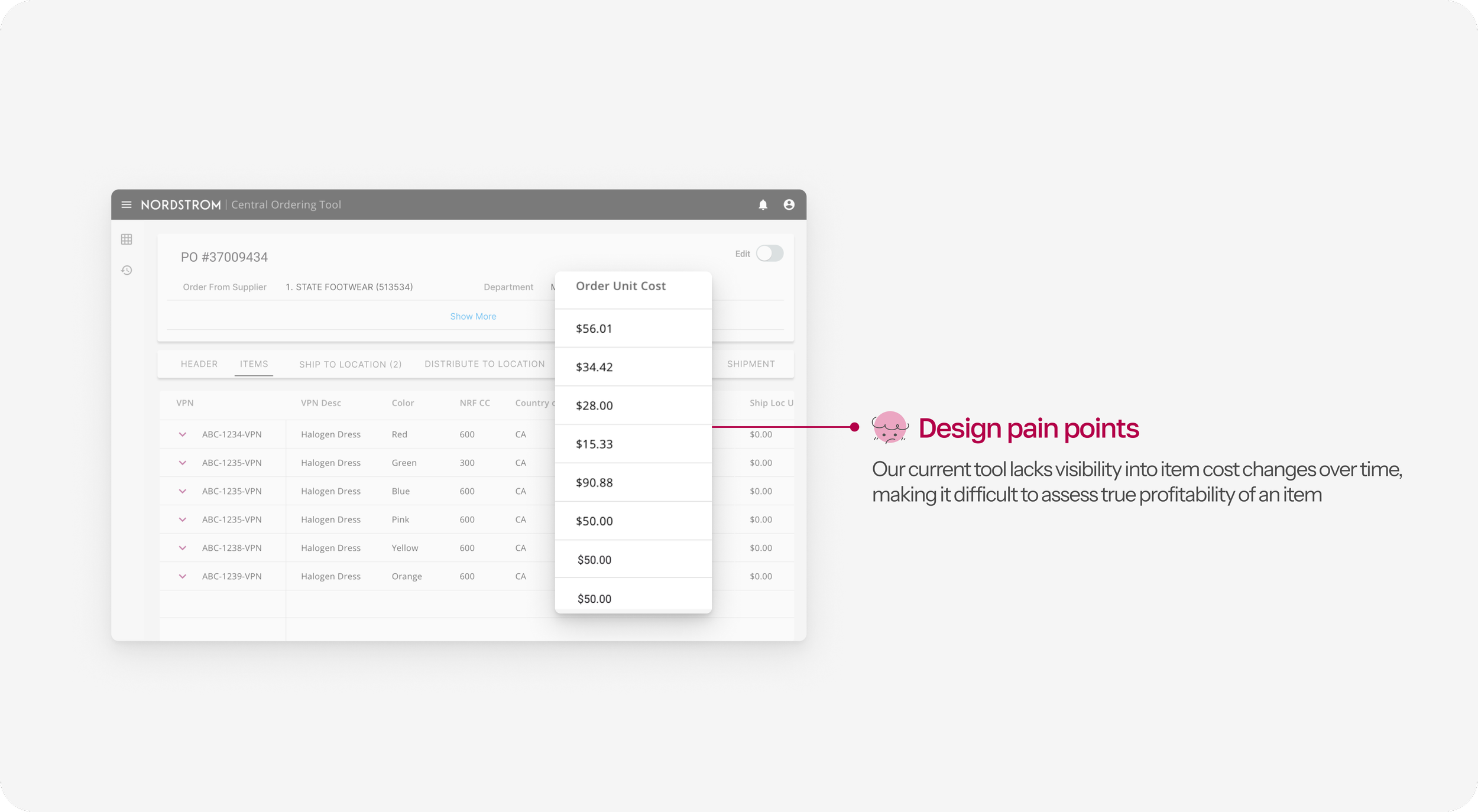

Employees dealt with frequent mistakes and inconsistencies in purchase orders because of manual entries and disconnected tools. They had no reliable way to verify cost accuracy, making it hard to trust the data for decision-making. These problems slowed down workflows, as employees spent a lot of time fixing errors instead of doing higher-value work.

For business: Inaccurate financial picture

Teams couldn’t see true profitability because inaccurate data made it hard to understand actual costs and margins. Approvals were slower and selling took longer, causing operational delays. Using multiple tools created inefficiencies and added complexity.

Challenges and Solutions

Fragmented workflows

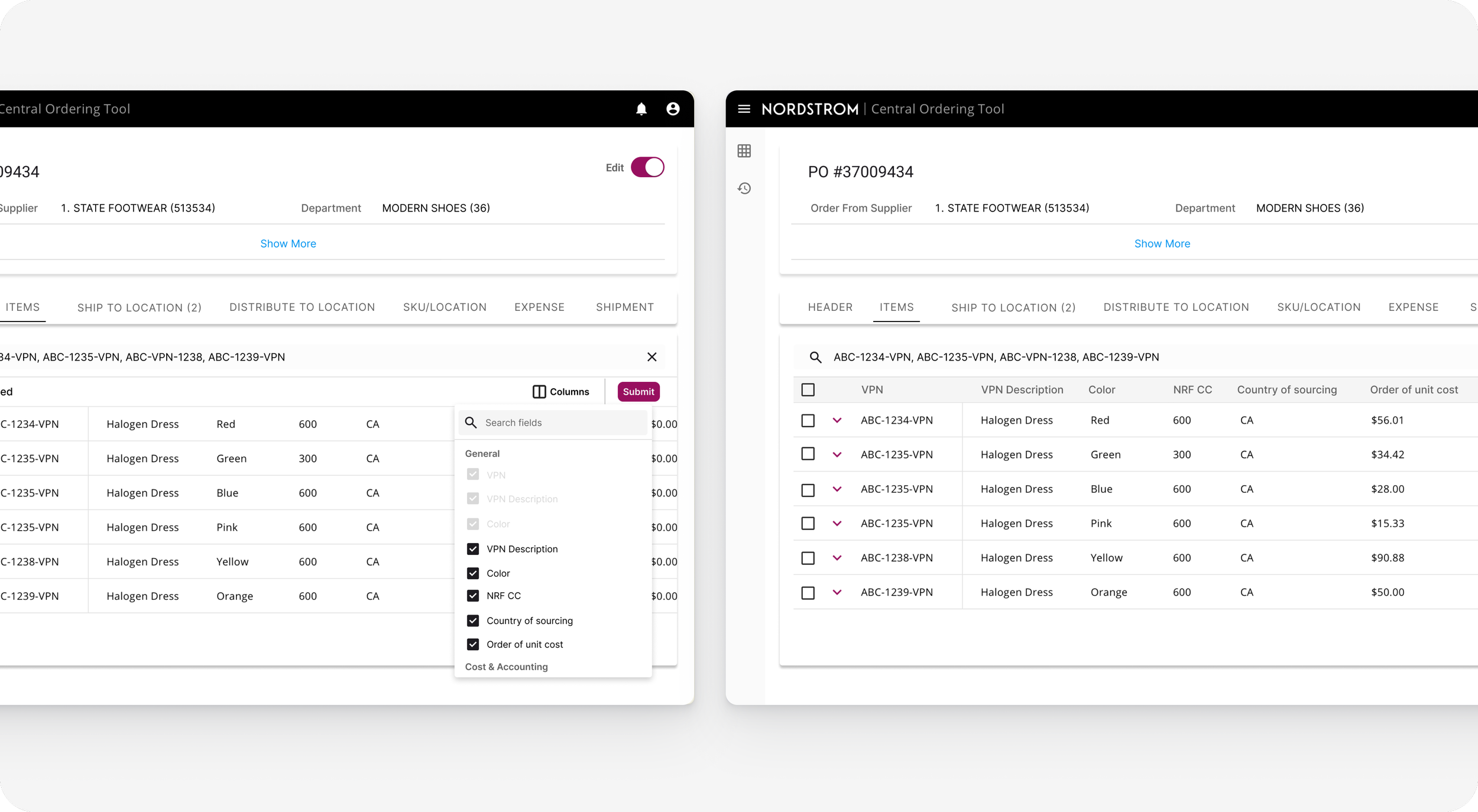

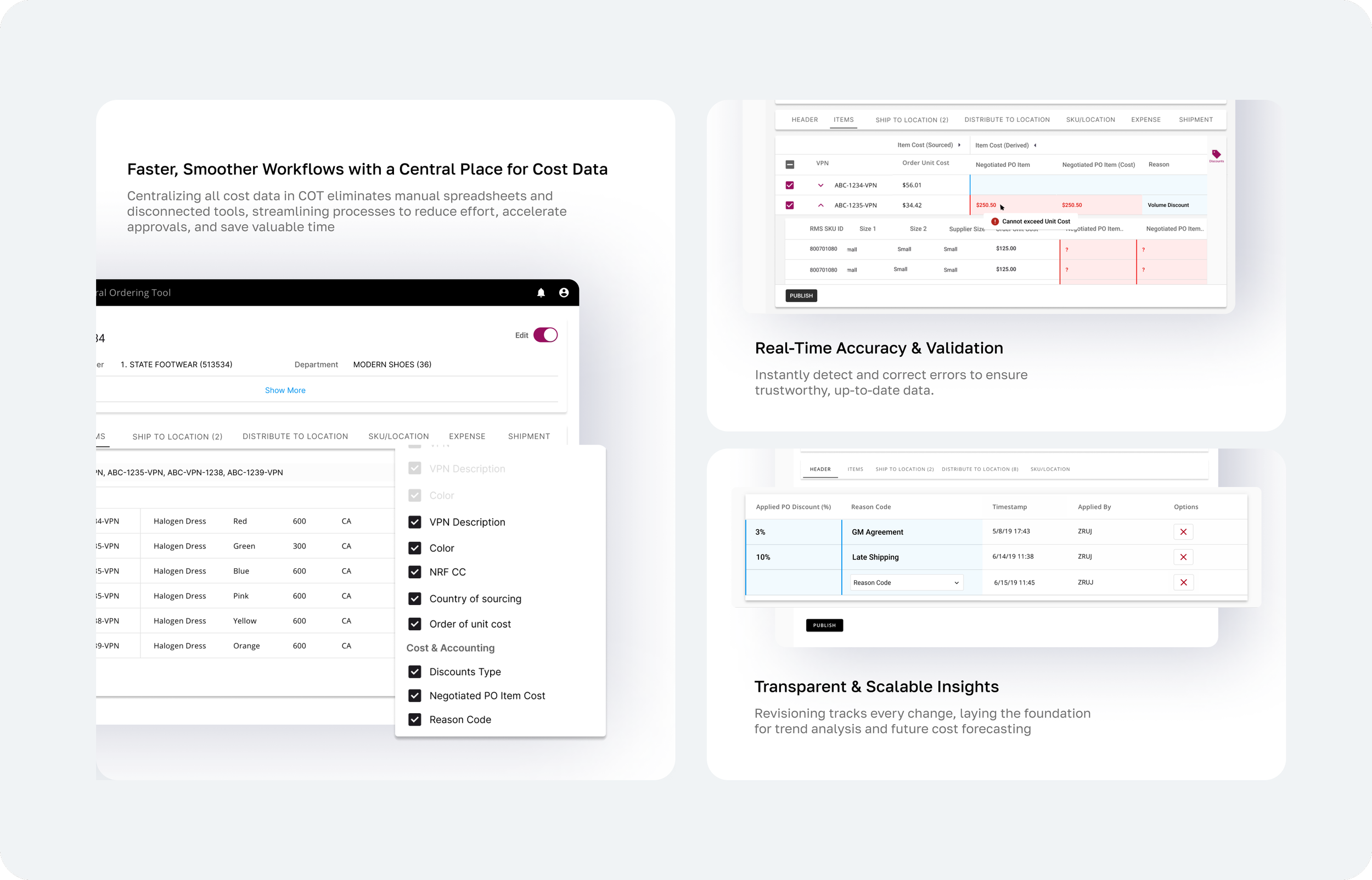

Employees relied on multiple external tools and manual entries to apply and validate purchase order data. This created inconsistencies, errors, and significant time spent reconciling information. I worked closely with Digital Operators and Buyers to map their workflows and identify overlaps. By consolidating all cost-related data entry into the Central Ordering Tool (COT) and dive deep in business requirements , we eliminated multiple external tools, streamlined workflows, and gave users one reliable source of truth.

Misaligned priorities

The project began with lack of unified understanding of success. While some prioritized speed, others emphasized accuracy or visibility. To create alignment, I facilitated working sessions with PMs, Finance, and Merch Analysts to define shared outcomes. Together, we set clear goals around reducing manual effort, improving data accuracy, and increasing trust in cost calculations—ensuring design decisions were grounded in measurable business impact.

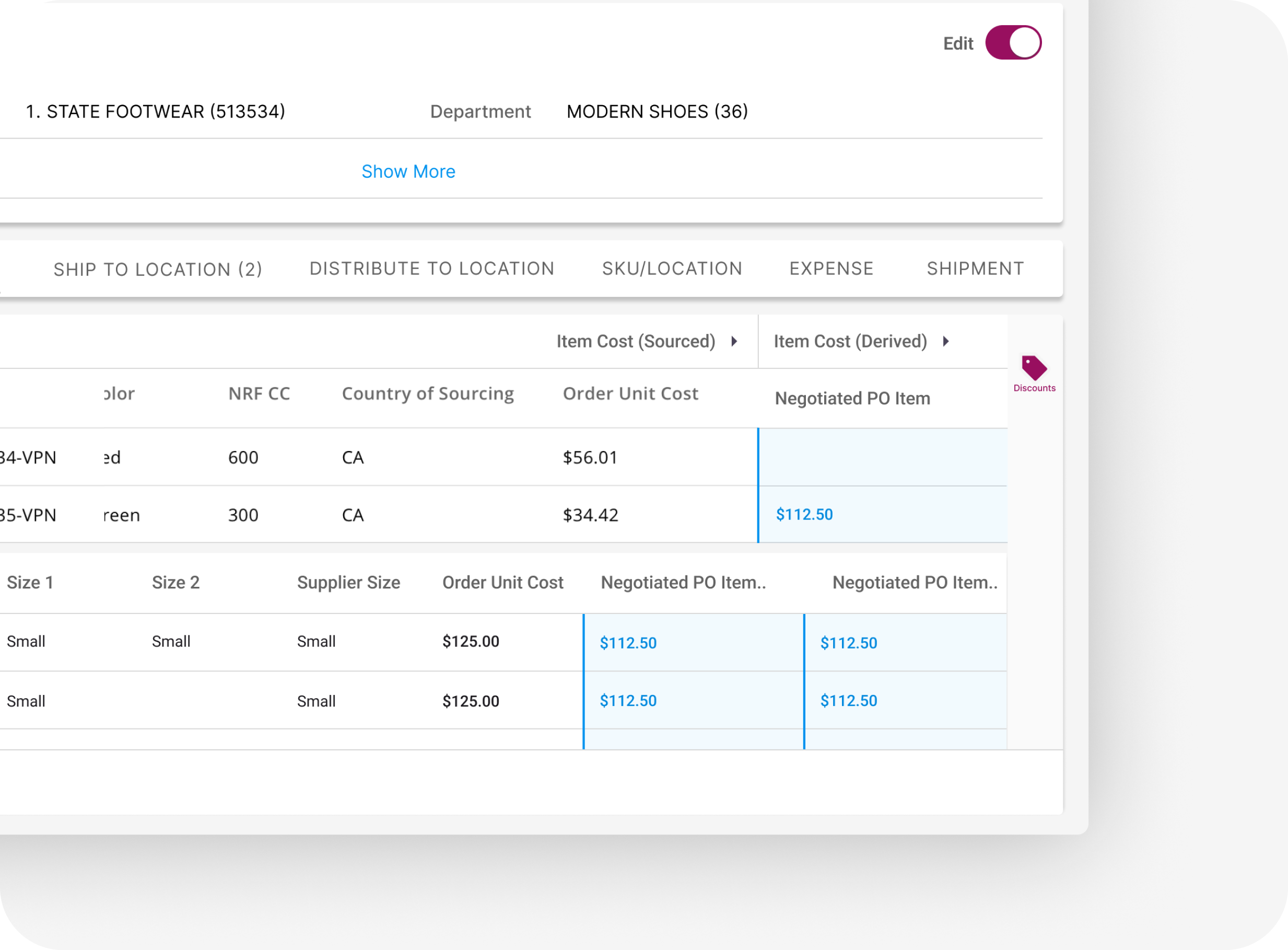

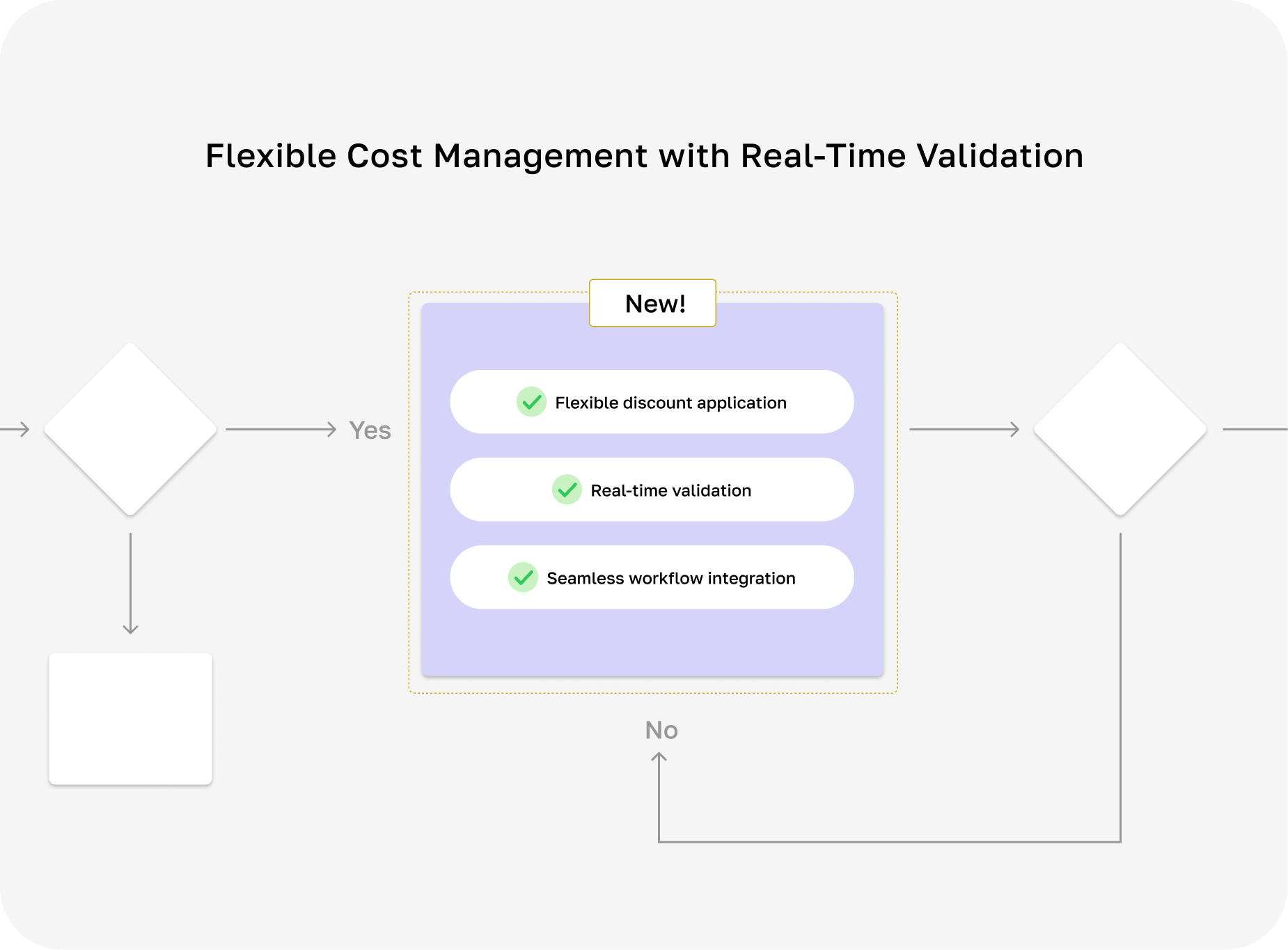

Lack of Discount Flexibility

Users needed a way to apply discounts at both the order and item levels, but the existing process lacked flexibility and visibility. This led to confusion and inconsistent data across teams. Through usability testing, I validated that users wanted both a high-level overview of total discounts and the ability to drill into details. I designed a consolidated discount section in the Purchase Order summary, enabling full traceability and standardization while fitting seamlessly into existing workflows

Learnings and Next Steps

Centralized cost management for all purchase orders

We unified cost tracking in COT, removing external tools and manual spreadsheets. Real-time revisioning now ensures accuracy, transparency, and faster approvals. With a single source of truth, users can view item-level profitability, reduce errors, and make data-driven decisions.

Next, we’re enhancing data accuracy and adding historical dashboards to uncover trends, forecast costs, and refine pricing strategies.